Outrageous Tips About What Is The Most Common Cause Of Undercut Too Prom Hairstyles For Long Hair How To Do

Let’s take a closer look at the causes.

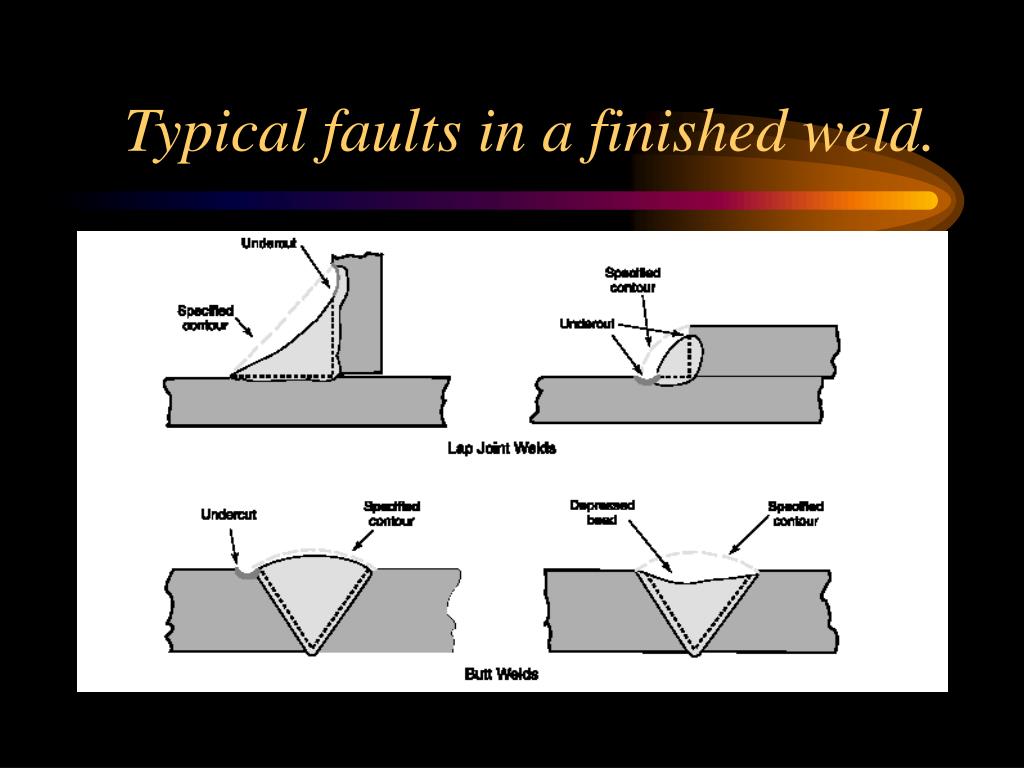

What is the most common cause of undercut too. Undercut defects are irregular grooves formed in the shape of notches on the base metal. The main cause of welding undercut is the angle of the torch in relation to the workpiece. Hyperkalemia can happen if your kidneys don’t work properly and cannot remove potassium from your body or if you take certain medicines.

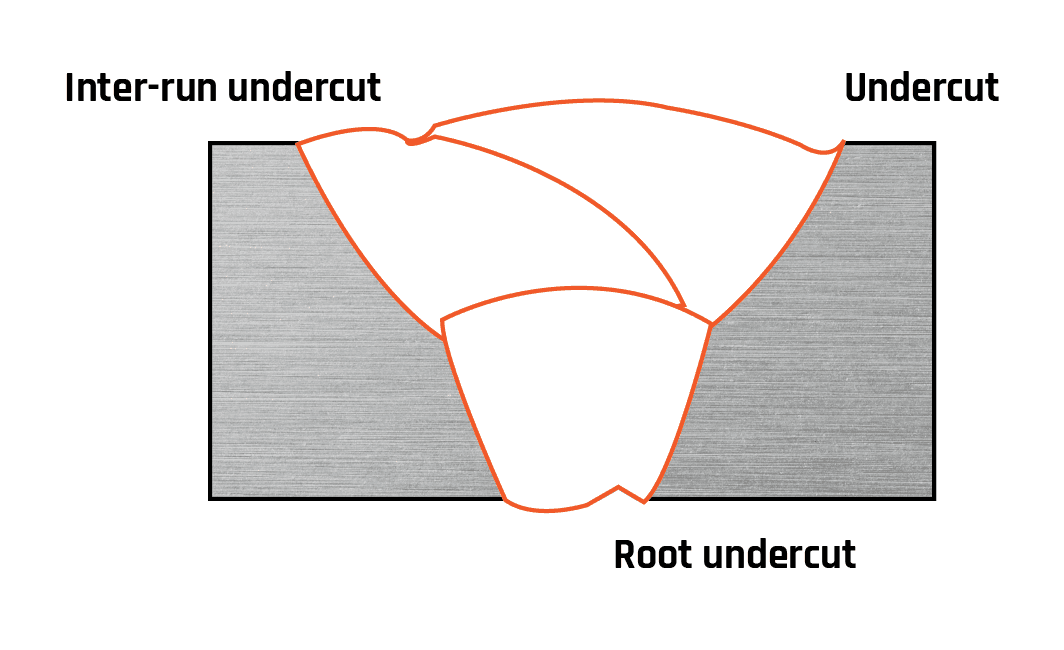

When the weld metal does not fill in the grooved area, it is known as undercutting. This leads to a weak weld with potential fractures along the toes of the weld. Diffuse hair loss involves loss of hair evenly across the scalp.

The primary causes of undercut in welding are wrong welding parameters, incorrect electrode and shielding gas selection, and poor welding techniques. Undercutting can often occur at the root pass of a welded point. This undercut can compromise the integrity of the weld, leading to structural.

Undercutting can be caused by maintaining to long of an arc length. If the torch is held too close to the workpiece, the heat will cause the. If you ingest a large amount of warfarin,.

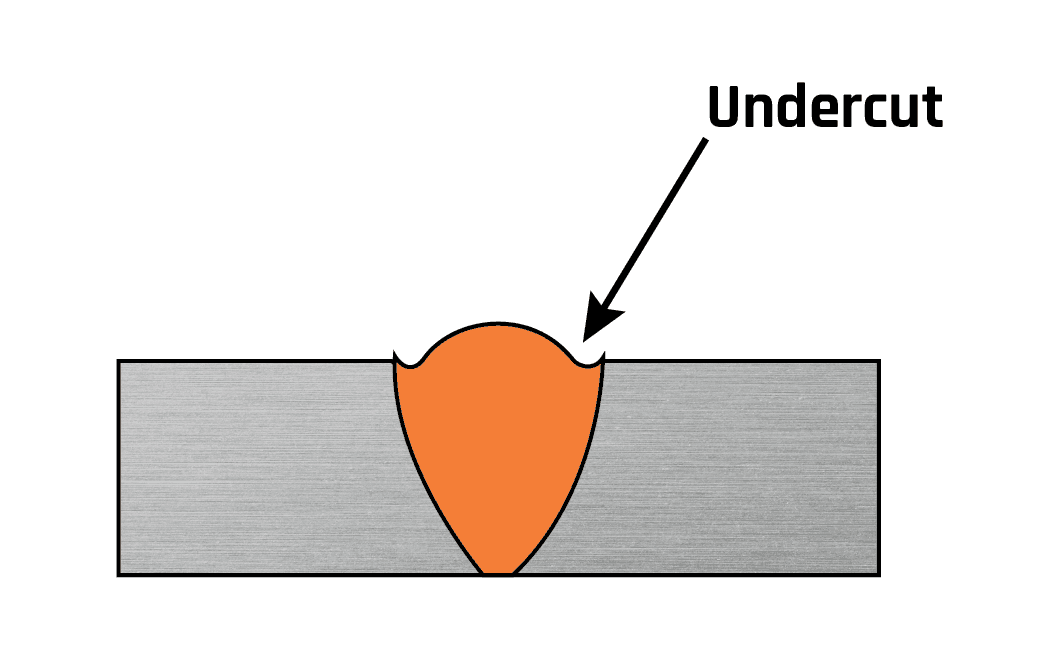

Undercutting is one of the most common welding defects. Fast welding is a common cause of undercuts. An undercut is usually produced from overheating and poor welding technique.

First, the welder may select the wrong welding parameters. Undercut is a common welding defect that can occur when the welding arc is too long, the welding angle is too steep, the current is too high, or the travel speed is too. When you weld too quickly, the base metal tends to become molten metal, and on most occasions, fails to return to its initial shape.

The result is the weakened. We’ll cover all the ins and outs below. Poisons that can cause hair loss include arsenic, thallium, mercury, and lithium.

Mostly, undercut occurs because of three mistakes. One of the most common complications in welding is an undercut, creating weld defects that are unpleasant to the eye and weaken the joint. Then, it also can occur because of electrode and.

When the welding wire used is too thin and the machine is set at a high voltage, you may have problems with. What is the main cause of undercut in welding? One such defect is called undercut, and it occurs when the arc length is too small for a given electrode extension resulting in searing and melting the base metal at.

They occur due to the melting of the base of metal away from the weld zone. The most common form of diffuse hair loss is telogen effluvium, which results in loss of more than. There are many reasons why an undercut can occur: